Catalysts and

molecular sieves are two critical components in industrial chemistry, working

together to drive efficient and sustainable chemical processes. While catalysts

accelerate reactions without being consumed, molecular sieves act as precision

tools to enhance catalytic performance through selective adsorption and

structural control. This article explores their interconnected roles and

applications.

1. What Are

Catalysts?

Catalysts are

substances that increase the rate of chemical reactions by lowering activation

energy. They remain unchanged at the end of the reaction, making them reusable.

Common examples include enzymes in biological systems and platinum in

automotive catalytic converters.

2. Understanding

Molecular Sieves

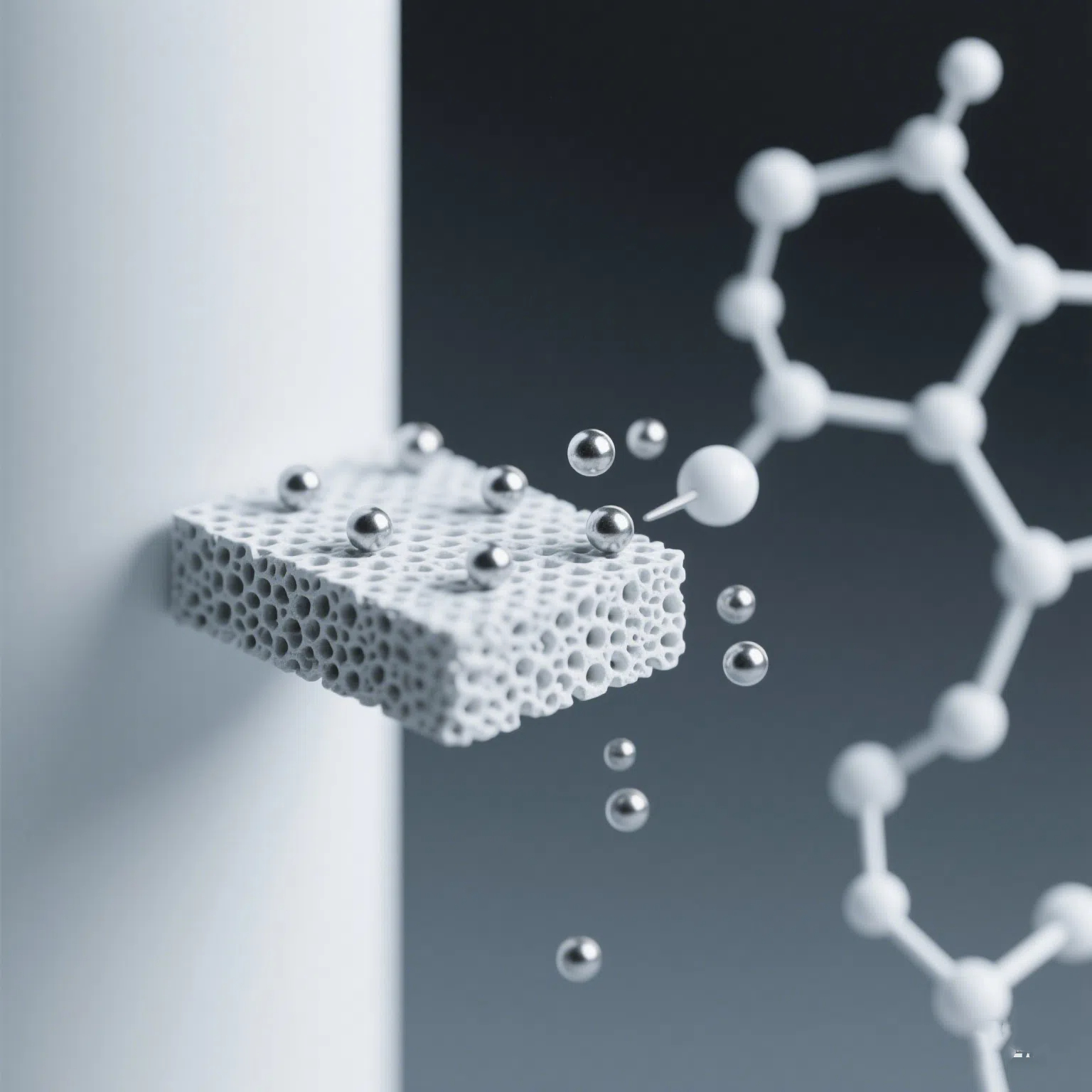

Molecular sieves are

porous materials with uniform pore sizes, typically made of aluminosilicates

(zeolites) or synthetic frameworks like MOFs (Metal-Organic Frameworks). Their

structure allows them to selectively adsorb molecules based on size and polarity.

Key properties include:

High surface area:

Enhances contact with reactants.

Uniform pore size:

Filters molecules by size (e.g., 3Å, 4Å, 5Å sieves).

Thermal stability:

Withstands high temperatures in industrial processes.

3. Molecular Sieves

as Catalysts

Certain molecular

sieves, such as zeolites, possess intrinsic catalytic activity due to their

acidic sites. For example:

Cracking hydrocarbons:

Zeolites like ZSM-5 break down large petroleum molecules into gasoline in Fluid

Catalytic Cracking (FCC) units.

Shape-selective

catalysis: Their pores restrict reactant/product sizes, ensuring only specific

reactions occur. This is vital in producing chemicals like *para-xylene* for

polyester manufacturing.

4. Molecular Sieves

as Catalyst Supports

Molecular sieves

often serve as supports for active catalytic metals (e.g., Pt, Pd, Ni).

Benefits include:

Dispersion:

Nanoparticles are evenly distributed on the sieve’s surface, maximizing

reactivity.

Stability: Prevents

catalyst sintering at high temperatures.

Selectivity: Pores

control access to catalytic sites, reducing unwanted byproducts.

Example: In

hydrogenation reactions, nickel-loaded zeolites selectively convert unsaturated

hydrocarbons into saturated ones while blocking larger contaminants.

5. Advantages Over

Traditional Catalysts

Efficiency: Higher

surface area improves reaction rates.

Sustainability:

Reduces waste by minimizing side reactions.

Reusability:

Molecular sieves are thermally stable and regenerable.

6. Industrial

Applications

Petroleum refining:

Zeolite catalysts produce cleaner fuels.

Environmental

remediation: Sieve-supported catalysts break down pollutants like NOx and VOCs.

Pharmaceuticals:

Enable precise synthesis of chiral molecules.

7. Challenges and

Future Directions

While molecular

sieves enhance catalysis, challenges include:

- High synthesis

costs.

- Pore blockage

(coking) in prolonged use.

8. Conclusion

Catalysts and molecular sieves form a powerful duo in modern chemistry, enabling cleaner, faster, and more selective reactions. From fuel production to pollution control, their synergy drives innovation across industries. As technology advances, this partnership will play a pivotal role in achieving greener chemical processes.