Introduction

In the global push for cleaner air and stricter environmental standards, the

oil refining industry faces immense pressure to reduce sulfur content in

transportation fuels. Hydrodesulfurization (HDS) is the indispensable catalytic

process that makes this possible. At the heart of every HDS unit lies a highly

specialized catalyst, engineered to break down sulfur compounds and enable

refineries to produce Ultra-Low Sulfur Diesel (ULSD) and other clean fuels

efficiently and economically.

The "Why":

Stringent Sulfur Regulations

Worldwide, governments have implemented drastic regulations to limit sulfur in

diesel and gasoline to mere parts per million (ppm) levels. For example:

Euro V/VI standards: <10 ppm sulfur in diesel

China VI standards: <10 ppm

India BS-VI standards: <10 ppm

High sulfur emissions lead to acid rain and harmful particulate matter (PM2.5). HDS technology is not just a process—it's an environmental imperative, and the catalyst is its engine.

The "How":

The Science of HDS Catalysts

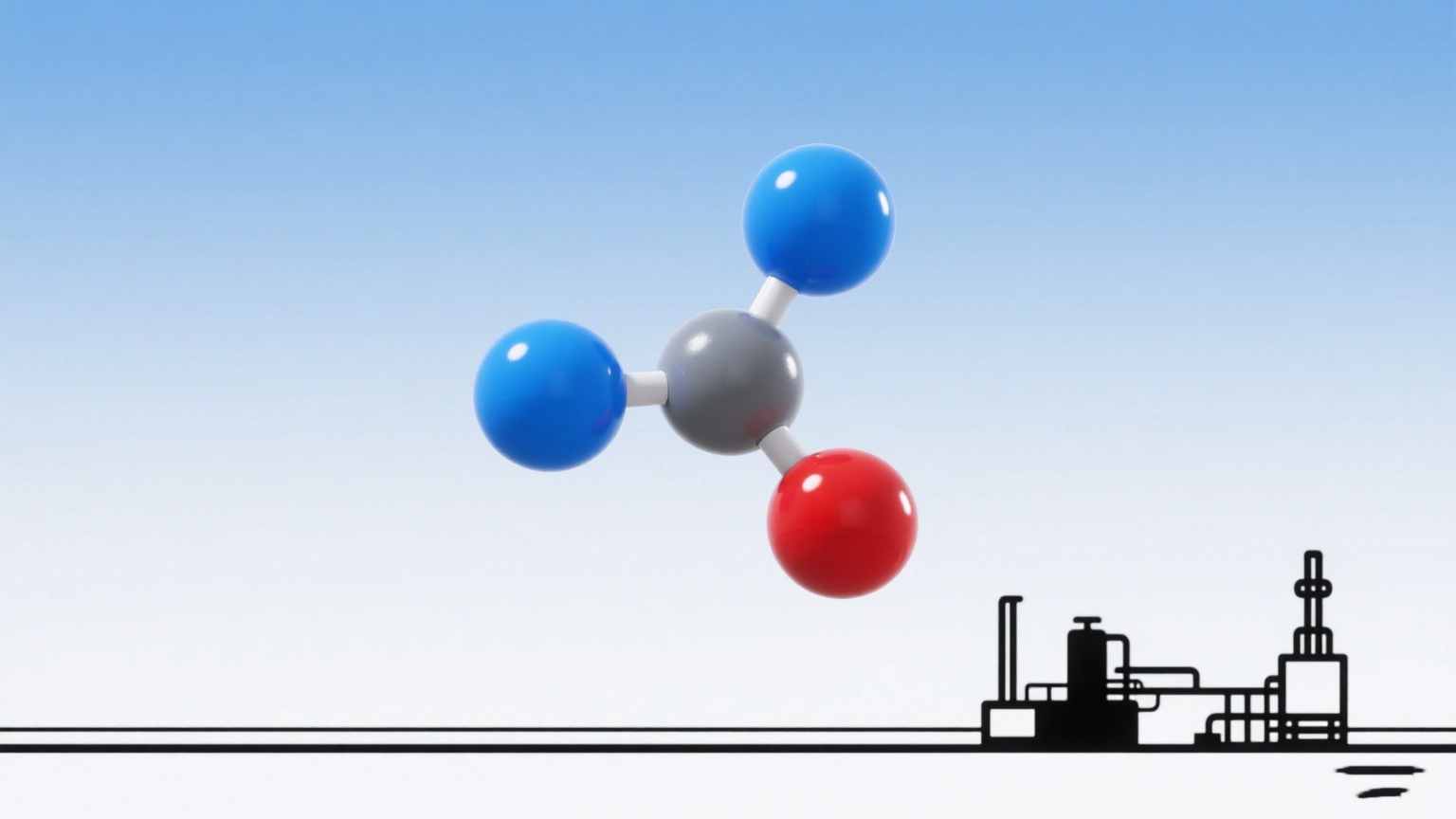

HDS is a hydrotreating process where feedstock (like diesel or naphtha) is

mixed with hydrogen and passed over a fixed bed of catalyst at high temperature

and pressure. The catalyst facilitates the reaction that breaks C-S bonds in

sulfur-containing molecules, converting them into hydrogen sulfide (H₂S) and

hydrocarbon parafins.

The most common catalytic systems are:

Cobalt-Molybdenum (Co-Mo) on Alumina support: Excellent for straight-run feeds and olefin saturation. Highly selective for removing simpler sulfur compounds like mercaptans and sulfides.

Nickel-Molybdenum (Ni-Mo) on Alumina support: More active for desulfurizing refractory sulfur compounds (like dibenzothiophene and its derivatives) which are harder to break down. Essential for achieving ultra-low sulfur levels (<10 ppm) and also offers strong denitrogenation activity.

Nickel-Tungsten (Ni-W): Sometimes used for highly aromatic feeds or extreme deep desulfurization.

Choosing the Right

Catalyst: Co-Mo vs. Ni-Mo

The selection depends on the feedstock and target:

Use Co-Mo Catalysts for lighter feedstocks and where primary sulfur removal is needed without excessive hydrogenation of aromatics.

Use Ni-Mo Catalysts for heavier, more complex feedstocks (like cracked gas oils) and when the goal is to achieve ULSD specifications. Ni-Mo is the workhorse for deep desulfurization.

Beyond Sulfur

Removal: The Multifaceted Role of HDS

While sulfur removal is the primary goal, a modern HDS catalyst simultaneously

improves fuel quality by:

Dentrogenation (HDN): Removing nitrogen compounds that poison downstream catalysts (e.g., in catalytic crackers).

Olefin Saturation: Improving fuel stability by hydrogenating reactive olefins.

Metal Removal: Acting as a guard bed to trap metals like nickel and vanadium from residual feeds, protecting the entire catalyst system.

Maximizing Catalyst

Performance and Life

A catalyst's life is key to refinery economics. Factors affecting HDS catalyst

performance include:

Pore Architecture: Optimized pore size distribution ensures access for large sulfur molecules in heavy feeds.

Active Phase Dispersion: Advanced manufacturing ensures maximum exposure of active Co-Mo or Ni-Mo sites.

Operating Conditions: Temperature, pressure, and hydrogen purity are carefully controlled to maximize efficiency and lifespan.

Catalyst Regeneration: Spent catalysts can often be regenerated (burning off coke deposits) to restore much of their activity, offering significant cost savings.

Conclusion: A

Strategic Investment in Compliance and Efficiency

Selecting the right HDS catalyst is a critical strategic decision for any

refinery. It is not merely a consumable but a core asset that determines the

ability to comply with environmental laws, process opportunity crudes, and

protect downstream units. A high-performance catalyst translates directly into

higher throughput, longer run lengths, and superior product quality—directly

impacting the bottom line.